unit of impact tester|examples of impact testing : purchaser In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. WEBSuch slots also come with several other amazing bonus features. They range from wilds, scatters, free spins, and more. The most common 5-reel online casino slots for real money in the US include Mega Moolah, Starburst, National .

{plog:ftitle_list}

webTrecho do episódio

Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180. The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. This singular point test offers a .Notched Izod Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

What Is the IZOD Test? The IZOD test is a way of determining the impact resistance of a material, specifically how much load it can handle before it breaks. This will help you choose the right material for your needs.What is an impact test? It is when a load is applied to a specimen, generally at a high velocity, then measuring the response of the specimen. There is a two-step process when breaking the .

Impact tests are designed to measure the resistance to failure of a material to a suddenly applied force such as collision, falling object or instantaneous blow. The test measures the impact energy, or the energy .

One of the most common tests, at least in the United States, of the physical characteristics of plastic materials is the notched izod impact test as specified by ASTM D256 Standard Test Method for Determining the Izod . The ISO method is slightly different, deriving impact strength with units kJ/m2 from the impact energy in J by the area under the notch. This test is performed on 10 specimens and the results are averaged. . While impact . The Impact Tester is a widely used device for the coating and plastic industries. In both industries impact resistance is measured by a falling weight from a.The chip impact test was originally developed in order to measuring the effect of surface microcracking caused by the weathering. The toughness of the material is measured in this test as opposed to the material notch sensitivity in an Izod measure, this method is in fact a variation of the Izod method previously described. .

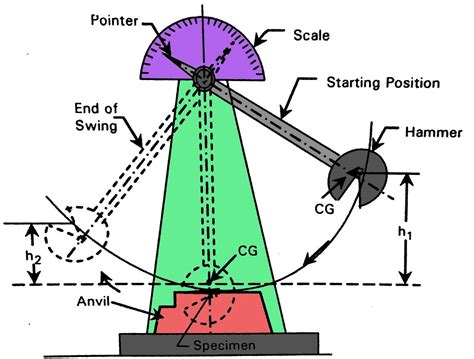

Base Unit. The Elcometer 1615 Variable Impact Testers are designed to meet a wide range of National and International Standards. Simply select the appropriate kit and attach the punch, die and accessories to the base unit. Interchangeable die - enables the user to match the die to the size of the relevant punch to conform to the required . Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180 The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. . The results can be represented in terms of energy lost per unit of thickness at the notch, such as ftIn addition, the dart drop tester provides a dual clamping sequence. The first phase utilizes low-pressure to safely clamp the sample followed by a high-pressure clamp prior to testing. The final phase of the test is completed with an automatic dart release. ASTM D1709 – Method A Dart 38.1 mm diameter Drop height .66 m (26 in) Dimensions (W x . Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads.

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on .

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be . Charpy impact test is a comparative style test used to define a material’s impact strength. Learn more about it here. . The energy absorbed must be divided by the cross-sectional area of the sample at the V-notch to calculate the impact strength. The unit of impact strength is J/m2. Repeat Test: . What is an Izod / Charpy Impact Tester? The Izod and Charpy impact testers are both used to measure the impact resistance of materials, specifically metals and plastics.. The Izod impact test involves striking a notched specimen with a pendulum. The energy required to break the specimen is measured and reported in units of joules per meter.The technique is for calculating the energy absorbed during a metallic material impact test. 3. EN 10045 is a test that adheres to European Standards. This is applied in the Charpy Impact Test for castings made of iron and steel. Video 01: ASTM D256 Izod Impact Strength Test – QC-639R(U) Computerized Impact Tester

Impact testing is used to measure an objects, material, or coatings ability to resist high-rate loading, normally thought of as two objects colliding at high relative speed. A coating's ability to resist impact is one of the major determining factors in the service life of a part and/or it's suitability for an application. The ability to quantify this property is a great advantage in product . The IZOD impact test is a standardized method that determines a material’s toughness and impact resistance. Learn more about it here. . This number will have a unit of J/m or ft-lb/in, which translates to the amount of kinetic energy that’s needed to . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Charpy impact testing determines the impact energy of materials.

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure . Choosing a pendulum unit. The most common impact testers sold today are pendulum units. Most of these accept different accessories (striker heads and specimen supports) in order to perform Izod, Charpy, and tensile-impact tests. Izod and Charpy tests are similar in many respects. Both use test specimens that are either molded to size or cut .

An impact test which is useful for testing paint and coating adhesion is ASTM D2794, the drop test performed on a universal impact tester (see top photo). We have two impact testers to evaluate a variety and sizes of materials – a tabletop tester shown on the left, and a 14-foot tall model. We also built a six-foot tall tester for custom testing.

Unit of Impact was designed as a framework to help you fulfill your legal requirements, beautifully. Certified B Corps Impact is in your blood. So is certification, every three years. Unit of Impact helps you continuously track your impact, making re-certification easier and providing a communications platform for marketing your impact every year.

1. Reasons for Impact Testing Impact testing is performed to determine the energy absorbed or the energy required to fracture a unit under test (UUT). Take for example a straight-line collision, such as a car crash. Using the work-energy principle .

A pendulum impact testing machine is used to determine the impact strength or toughness of a material under impact loading by measuring the amount of energy the material is able to absorb. Knowing the energy absorption properties of a material is crucial for predicting how much plastic or permanent deformation the material can withstand before it fails.In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

hanna instruments hi 903 karl fischer volumetric titrator vendor

1. Reasons for Impact Testing Impact testing is performed to determine the energy absorbed or the energy required to fracture a unit under test (UUT). Take for example a straight-line collision, such as a car crash. Using the work-energy principle . The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. . The impact test is vital to the aerospace, construction, automobile and shipbuilding industries. Other industries that manufacture materials also need to have .Features of impact tester for plastic films. This impact tester for plastic films is used to assess the quality of packing films by calculating their resistance to free-falling weight during storage and transportation. It satisfies test requirements like IS 2508:1984(R2003), ASTM D1709-16A. Read out the features we are providing in our dart .

xometry impact test

why impact testing is done

Pinnacle Pelican Vacushield Stainless Steel Hot & Cold Bottle With Handle, 1500 ML PRO-GRADE STAINLESS STEEL - Durable pro-grade Stainless Steel won't retain or transfer flavor, ensuring the beverage to remain pure for a long period of time. COPPER COATING - Premium copper caoting for additional layer of insulation. .

unit of impact tester|examples of impact testing